PLASTONE

Your one-stop partner in thermoplastics subcontracting

Support for product development

Involvement of manufacturer from the early stage of product’s life cycle ensures effective production and material-technical solutions.

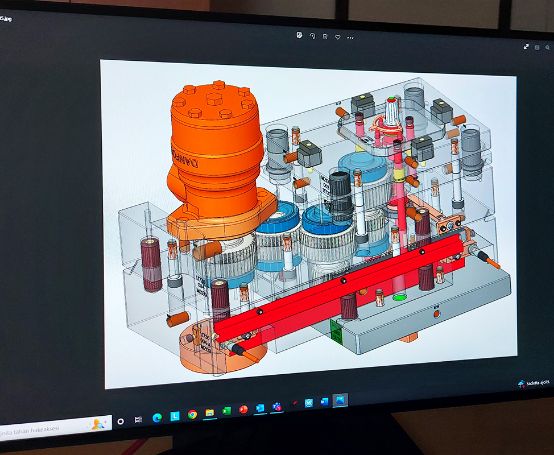

Mould design and production

Process from the idea until final product is rather long and one of the most important things in getting the product on the market is designing and producing a high quality mould.

Plastic production

Continuous production development like automation and using of robots in various stages of injection moulding ensures competitive prices for plastic parts serial production.

Cleanroom manufacturing

Regular production environment is not always sufficient and controlled conditions meeting ISO 14644-1 standard are needed to fulfill the requirements for product cleanliness.

Assembly works

Continuous production development and automation are part of Plastone’s everyday activities. Still, automation is not always rational and therefore human labor is needed for different assembly processes

Our brochure

Our latest brochure now available on-line.

Product groups

Contact us

Contact us with this form. You can tell us what you are interested in or how we can help you. We will contact you as soon as possible.

*Fields marked with a star are required.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

News

- Plastone is now part of KB ComponentsKB Components AB from Sweden acquired the entire business of Plastone Finland Oy and Plastone OÜ on December 20, 2024.… Read more: Plastone is now part of KB Components

- EcoVadis 2024Plastone has once again received a medal-worthy recognition for its sustainability in the EcoVadis assessment. As part of the Saxo… Read more: EcoVadis 2024

- Plastone Oy is planning a demergerPlastone Oy plans ot separate its real estate operations into its own company. For this, Plastone Oy has registered a… Read more: Plastone Oy is planning a demerger